Rigid HVAC Ducting at Murrieta Public Library

Pilot Program in cooperation with The City of Murrieta, Southern California Edison and Deep Energy Solutions.

ACS CIC 4.0 was applied to the HVAC ducting Reduce Solar Heat Loading, Seal Duct Joints and Eliminate Rust and Corrosion

Product: ACS CIC 4.0

Goal: Reduce Solar Heat Load, Seal duct joints, eliminate corrosion

REDUCE HEAT LOAD CAUSED BY RADIATION

Radiation causes heat from the sun to warm the surface of the ducting. Conduction is the movement of heat from hot side toward the cold side through the walls of the ducting which causes air in the duct to warm up on a hot day. Convection within the duct circulates the air within the duct. The loss of cold air is shown in the diagram to the left. After the coating was applied the surface temperature of the ducting was reduced up to 69°F combined with the continuous membrane eliminated the loss of cold air.

SEAL JOINTS THAT ARE CRACKED AND RUSTED

The duct sealant at the joints has failed and there is rust under the sealant that indicates condensation.

Deep Energy Solutions power washed the ducts with a vinegar solution to remove the loose joint material as well as build-up of dirt.

The application of CIC ACS CIC 4.0 provided a continuous membrane that sealed the joints along with the entire duct.

An average duct has R-5 insulation inside the duct. This traditional type of insulation has been proven to fail with the moisture of condensation and presents a potential area of mold and mildew with in the duct and contributes to corrosion under insulation.

MONITORING THE PROJECT:

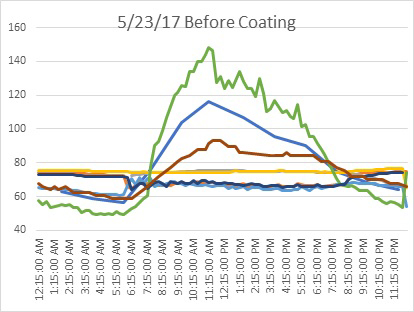

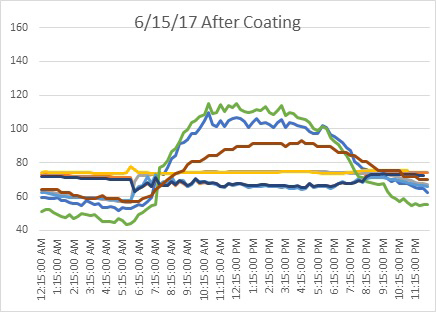

The HVAC system for the Murrieta Library is located on the roof top and is subject to full sun and solar heat loading. Remote temperature sensors were used to record temperature before and after coating.

Two Days were selected for comparison, May 23, 2017, which was the hottest day before the coating was applied and June 15, 2017 after the coating was applied. These days were selected because they both had a high temperature of 93.2°F according to wunderground.com

These graphs demonstrate that the coating reduced the surface temperature of the ducting up to 25°F and reduced the heat loss within the ducting by up to 4°F. Additionally, there is a motion sensor that shows that the HVAC unit is cycling on and off after the coating was installed where before the coating was installed the unit came on in the morning and ran all day.

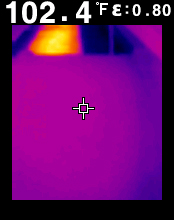

FLIR IMAGE AND LOCATION SHOTS.

The following temperature measurements with recorded with a FLIR TG154 and a location and an image of where the temperature reading was taken for reference. Before Images were taken on 6/3/2017 9:30 AM with an ambient temperature of 77°F and the after images were taken on 6/30/2017 10:30 AM with an ambient temperature of 75°F. This the leaking joints have been sealed and the ducts are not experiencing solar heat loading or conduction through the ducts or joints.

CONCLUSION

This application of CIC ACS CIC 4.0 increased the energy efficiency of the ducting and qualified for a rebate under SCE Solution AC-40390 within the Customized Solutions program. The CIC ACS CIC 4.0 extended the useful life of the ducting by twenty years eliminating the need for the city to replace the ducting.